Pinepac produces Anchor Piles in lengths of 1.5, 1.8, 2.4, 3.0, and 3.6 meters, with each packet containing 55 pieces.

ANCHOR PILE DEFINITION

Anchor Piles are designed to withstand lateral loads, either braced or unbraced, depending on the circumstances, while standard house piles bear vertical loads. Used in critical applications, Anchor Piles possess significantly higher strength characteristics compared to ordinary piles. Excerpts from NZS 3605:2001 provide insight into the strength values and general requirements of Anchor Piles.

The lateral load capacity of timber pile foundation systems is outlined in NZS 3604. Anchor Piles and braced piles, which are subjected to the highest loads, require a capacity of 160 Bracing Units (BUs), while driven cantilever piles must have a capacity of 70 BUs. Considering the seismic response and maximum permitted height, the bending moment demand for the anchor, driven cantilever, and braced piles is 6.0, 4.7, and 4.4 kNm, respectively. Anchor Piles require special care in selection, with proof testing being the only method to ensure their strength. Ordinary piles support vertical loads and require minimal bending capacity.

Strength testing of Anchor Piles requires sustaining a proof test bending moment of 5 ±0.25 kNm, as outlined in Appendix B, or annual proof testing in batches of 100 piles to a bending moment of 6 ±0.3 kNm, as described in Appendix A.

Anchor Piles, made from Pinus species, are treated to Hazard Class H5 according to NZS 3640. Any processing after treatment requires brush treatment with a timber preservative. Fixings and other attachments should not cut the surface closer than 150mm from the finished ground level.

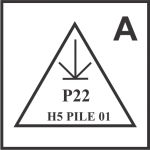

Anchor Piles must be branded according to NZS 3640, with the brand placed one-third of the length from the top and facing upwards. The letter “A” must be incorporated into the brand.

◄ Example of an “A” Anchor Pile Identification Mark:

All other identification marks as per ordinary piles and shall meet the requirements of NZS 3640.