Pinepac Group produces E-frame™ Structural Timber, a kiln-dried, machine-graded timber renowned for its exceptional strength and suitability for both residential and commercial construction. It is commonly used in wall frames, roof trusses, and load-bearing applications.

Available in SG8, SG10, and high-strength SG12 grades, E-frame™ is offered in sizes ranging from 2.4 to 6.0 meters, with color-coded markings for easy grade identification. The same advanced grading technology is used for beams, squares, piles, and scaffold planks, which come in either rough sawn or machined kiln-dried finishes, with sizes ranging from 75x40mm to 300x100mm.

E-frame™ is treated to various hazard classes, including H1.2 Boron, H3.1 LOSP, H3.2 CCA, and H3.2 ACQ, and meets Woodmark® quality standards. It provides a cost-effective solution for timber merchants, prenail, and truss manufacturers, and it is available in economical packs or customized to individual needs.

Manufactured using award-winning E-grader™ technology, developed by Forest Research and Falcon Engineering, E-frame™ complies with NZS 3604 and SG graded pine standards. New Zealand Forest Research confirms that SG8 meets strength requirements equivalent to visually graded No.1 framing (Sawmilling Bulletin, Issue No. 28, December 2000).

FEATURES & BENEFITS

- Made from sustainably grown New Zealand plantation pine.

- 100% true to grade, accurate, and consistent.

- High-temperature kiln-dried Radiata pine for faster close-ins and improved stability.

- Machine stress-graded for structural reliability.

- Excellent for nailing, plating, gluing, and screwing.

- Available in SG8 wet framing variant.

- Easily identifiable with ink branding indicating hazard class, treatment date, and grade.

- Meets NZ Standards: NZS 3603, NZS 3640, NZS 3622, and carries Verified Timber and NZ Dri licenses.

- Backed by full service and technical support from Pinepac Group.

Applications for Architects, Designers, and Drafting Specialists include:

-

Trusses | Rafters | Wall Frames | Mid Floors | Lintels

HANDLING & CARE

- Keep timber dry, wrapped, and off the ground using gluts.

- Schedule deliveries for just-in-time arrival.

- Avoid leaving frames on the ground.

- Treat nailed frames as dry timber and wrap them with building paper promptly.

- Don’t let minor moisture in the bottom plate delay cladding, as it will dry quickly once cladding is complete.

- Ensure accurate setup for 35mm or 45mm E-frame™ sizes.

- Dry midfloor joists to prevent issues with cladding and stairwells.

- Order window, door, and slider joinery to match E-frame™ specifications.

- Confirm hardware is suitable for 35mm or 45mm E-frame™.

- Check moisture content before lining; do not line over wet timber.

- Dispose of preserved wood at an approved landfill or by controlled incineration.

QUALITY ASSURANCE

Trust the reliability of Pinepac E-frame™, rigorously tested with the advanced E-grader™ and produced under the NZ Dri quality assurance license. Our NZ Dri branded timber ensures consistent performance, with each piece meticulously kiln-dried to meet the highest standards.

E-frame™ Kiln Dried Stress Graded Pine delivers top-tier quality and performance, ideal for those who demand the best.

Batch tests are available upon request for added peace of mind.

COMPLIANCE

E-frame™ meets the highest standards, fully compliant with NZS/AS:1748 for product requirements and NZS/AS:4063 for in-grade strength and stiffness. This guarantees consistent, top-tier products.

For details on framing sizes and structural grades, please contact us.

SAFETY GUIDELINES

- It is recommended to wear a dust mask, eye protection, and gloves when handling or cutting timber. Always prioritize safety while working.

- Wash work clothes separately.

- Dispose of waste in an approved landfill.

- Do not use sawdust or shavings as animal litter.

- Do not use treated wood for cooking or burning.

- Keep treated wood away from drinking water.

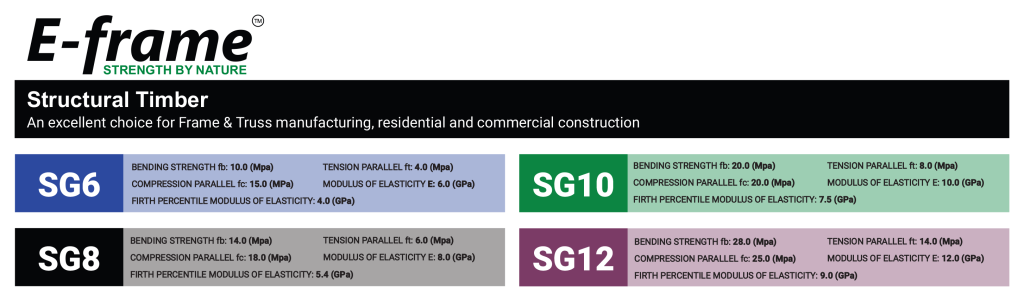

E-FRAME™ GRADE AND CHARACTERISTIC VALUES